Maintenance of silencing check valve

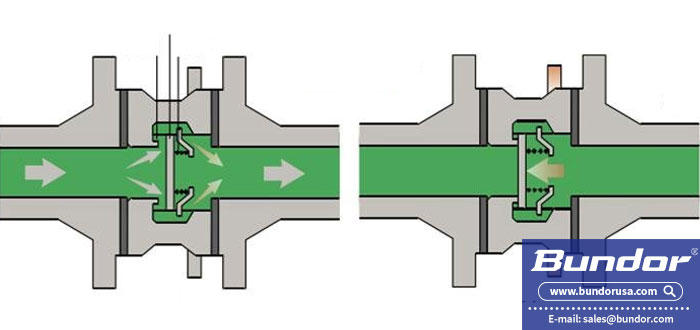

The silencing check valve belongs to the automatic valve category. Its function is to prevent the backflow of medium in the pipeline. It is mainly used in the pipeline with unidirectional flow of medium. It only allows the medium to flow in one direction to prevent accidents

The maintenance of silencing check valve is as follows:

1) During storage and transportation, the opening and closing parts should be in the closing device, and the following work should be done:

① The disc of the silencing check valve should be fixed in the open position.

② The inner ends of both ends of the path are blocked with foam boards, and the ports must be tightly covered with a stuffy cover to prevent dust and rust.

③ Proper packaging protection, shockproof and anti-collision should be carried out for cylinder parts.

2) The silencing check valve should be placed stably, with the pneumatic driving device facing upward, and should not be squeezed with each other.

3) Regular inspection should be carried out during long-term storage. Check the dirt and rust on the two channels and sealing surfaces every three months, and check the protection condition of the welding interface. After wiping the dirt and rust, brush the antirust oil again for protection.

4) In order to prevent reverse flow of medium, check valve should be installed on all of equipment, device and pipeline;

5) The silencing check valve is generally suitable for cleaning medium, not suitable for medium containing solid particles and high viscosity;

6) Generally, vertical silencing check valve should be selected on the horizontal pipeline with nominal diameter of 50mm;

The silencing check valve should be stored in a dry and ventilated room to prevent moisture, rain and rust.

The above is the knowledge sharing of maintenance and repair of silencing check valve. If you need to purchase or replace a new silencing check valve, or are looking for a suitable manufacturer, you are very welcome to contact with Bundor valve.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor