What is a swing check valve

Posted by Bundor valve

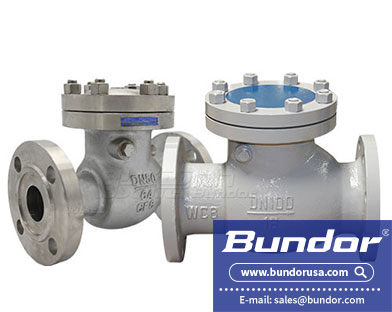

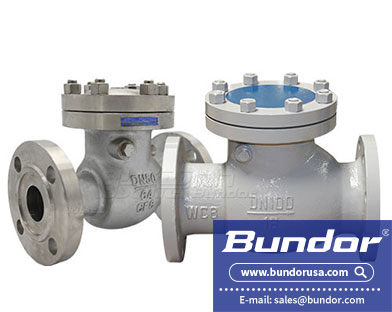

Swing check valve is also known as reverse (flow) valve, is used for one-way flow pipeline to prevent the media flow of the automatic valve, rely on the pressure of the pipeline media flow to open or close the valve, can be divided into single, double and multi - flap type three, belongs to one of the more commonly used valves.Swing check valve is generally suitable for the fluid medium is relatively clean in the pipeline, not suitable for viscosity or containing solid particles of the working condition, otherwise it will lead to the check valve is not sensitive to open, can not reach the complete seal, the fluid check is not reliable.Swing check valves allow media to flow in only one direction and effectively prevent media backflow to prevent accidents.

Swing check valve disc disc, around the valve seat channel for rotary motion, because the channel into the flow line, flow resistance is smaller than the lifting check valve, is suitable for low flow rate and flow is not often changed in large diameter occasions, but should not be used for pulsating flow, its sealing performance is less than the lifting type.

The swing check disc is connected to the rocker and can be rotated at an Angle around the pin.When the line fluid flows in the specified direction (from left to right), the disc inlet pressure is higher than the outlet pressure, and the disc is pushed off the seat, rotated around the pin, and the valve is in an open position.When the pressure difference between the two sides of the disc decreases to a certain level, the disc falls and returns to the closed position.When the fluid flow from right to left, namely reverse flow, the pressure on the right side of the disc is higher than the pressure on the left side, the pressure generated by the pressure difference between the two sides will disc pressed on the seat, the fluid can not pass, the medium can not flow back;And the greater the fluid pressure, the tighter the sealing surface pressure, the better the sealing effect.

Swing check valve disc disc, around the valve seat channel for rotary motion, because the channel into the flow line, flow resistance is smaller than the lifting check valve, is suitable for low flow rate and flow is not often changed in large diameter occasions, but should not be used for pulsating flow, its sealing performance is less than the lifting type.

The swing check disc is connected to the rocker and can be rotated at an Angle around the pin.When the line fluid flows in the specified direction (from left to right), the disc inlet pressure is higher than the outlet pressure, and the disc is pushed off the seat, rotated around the pin, and the valve is in an open position.When the pressure difference between the two sides of the disc decreases to a certain level, the disc falls and returns to the closed position.When the fluid flow from right to left, namely reverse flow, the pressure on the right side of the disc is higher than the pressure on the left side, the pressure generated by the pressure difference between the two sides will disc pressed on the seat, the fluid can not pass, the medium can not flow back;And the greater the fluid pressure, the tighter the sealing surface pressure, the better the sealing effect.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor