How to choose a steam valve

Posted by Bundor valve

The valve opening and closing parts of the steam valve and the shape of the valve flow channel make the valve have certain flow characteristics. This must be taken into account when choosing a steam valve.

For liquids such as condensed water, the valve for shutting off and connecting the medium is selected. Usually, the flow resistance is small and the flow channel is a straight-through and full-pass ball valve.

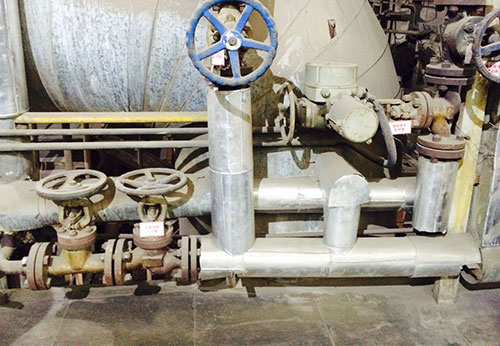

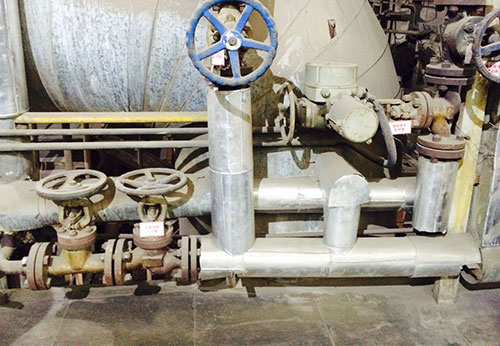

The bellows globe valve is commonly used in steam valves. The structure of the bellows globe valve is a downward closed valve. Due to the tortuous flow path, the flow resistance is higher than that of other rotary valves, but the spherical valve structure of the globe valve is adjusted and sealed by steam.

Usually, it is used for throttling by changing the shape of the disc of the globe valve. There are certain limitations in using the opening height of the globe valve to realize the throttling effect. Because the medium in the pipeline is in a throttled state, the flow rate is very high, and the sealing surface is easily washed and worn, resulting in a reduction in the cutting and sealing effect.

For steam, good throttling control can effectively control the starting speed of the steam system and avoid problems such as water hammer, vibration and noise caused by thermal shock and insufficient drainage of the steam system. Generally speaking, the equal percentage spool structure is more suitable for sub-cylinder and pressure reducing valve bypass, inlet valve of equipments’s applications.

Experience has shown that when the throttling valve core structure is used, the dryness (water content) of the steam will cause cavitation at the valve core of the steam valve, so that it cannot be completely sealed.

The quick-opening flat valve core is not easily affected by steam erosion and cavitation, but the quick-opening bellows-sealed steam shut-off valve often leads to aggravation of steam turbulence, which in turn leads to fatigue failure of the bellows. Reduce the service life of the bellows stop valve, and it is easy to cause water hammer when starting up, resulting in deformation of the valve stem.

The flat valve core structure is easy to be affected by solid impurities such as welding slag, resulting in irreversible sealing failure.

The quick-opening valve core structure with rectifying steps is conducive to the smooth flow of steam through the valve nozzle, and also reduces the impact of cavitation on the sealing surface. This structure is the widest choice for bellows-sealed steam globe valves.

The traditional plunger-type valve core structure and conical valve core structure are not recommended for steam systems, and this self-sealing valve core structure is not suitable for bellows-sealed globe valves.

The valve opening and closing parts of the steam valve and the shape of the valve flow channel make the valve have certain flow characteristics. The experience is that this must be taken into account when choosing a steam valve. The flow characteristics of the valve suitable for use are beneficial to prolong the service life of the bellows-sealed steam shut-off valve.

For liquids such as condensed water, the valve for shutting off and connecting the medium is selected. Usually, the flow resistance is small and the flow channel is a straight-through and full-pass ball valve.

The bellows globe valve is commonly used in steam valves. The structure of the bellows globe valve is a downward closed valve. Due to the tortuous flow path, the flow resistance is higher than that of other rotary valves, but the spherical valve structure of the globe valve is adjusted and sealed by steam.

Usually, it is used for throttling by changing the shape of the disc of the globe valve. There are certain limitations in using the opening height of the globe valve to realize the throttling effect. Because the medium in the pipeline is in a throttled state, the flow rate is very high, and the sealing surface is easily washed and worn, resulting in a reduction in the cutting and sealing effect.

For steam, good throttling control can effectively control the starting speed of the steam system and avoid problems such as water hammer, vibration and noise caused by thermal shock and insufficient drainage of the steam system. Generally speaking, the equal percentage spool structure is more suitable for sub-cylinder and pressure reducing valve bypass, inlet valve of equipments’s applications.

Experience has shown that when the throttling valve core structure is used, the dryness (water content) of the steam will cause cavitation at the valve core of the steam valve, so that it cannot be completely sealed.

The quick-opening flat valve core is not easily affected by steam erosion and cavitation, but the quick-opening bellows-sealed steam shut-off valve often leads to aggravation of steam turbulence, which in turn leads to fatigue failure of the bellows. Reduce the service life of the bellows stop valve, and it is easy to cause water hammer when starting up, resulting in deformation of the valve stem.

The flat valve core structure is easy to be affected by solid impurities such as welding slag, resulting in irreversible sealing failure.

The quick-opening valve core structure with rectifying steps is conducive to the smooth flow of steam through the valve nozzle, and also reduces the impact of cavitation on the sealing surface. This structure is the widest choice for bellows-sealed steam globe valves.

The traditional plunger-type valve core structure and conical valve core structure are not recommended for steam systems, and this self-sealing valve core structure is not suitable for bellows-sealed globe valves.

The valve opening and closing parts of the steam valve and the shape of the valve flow channel make the valve have certain flow characteristics. The experience is that this must be taken into account when choosing a steam valve. The flow characteristics of the valve suitable for use are beneficial to prolong the service life of the bellows-sealed steam shut-off valve.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor