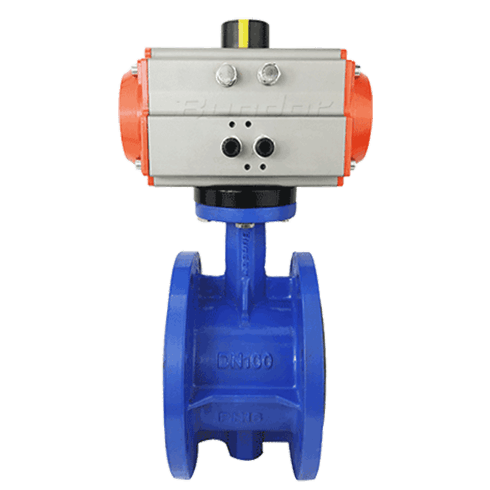

Introduction to pneumatic flange butterfly valve

Pneumatic flange butterfly valve structure working principle suitable for environmental analysis

Butterfly valve butterfly plate installed in the pipe diameter direction.In the butterfly valve body cylindrical channel, disc shaped butterfly plate around the axis of rotation, rotation Angle is 0°~90°, rotation to 90°, the valve is fully open.

Butterfly valve simple structure, small volume, light weight, only by a few parts.Moreover, the valve can be opened and closed quickly by rotating 90°, and the operation is simple. Meanwhile, the electric valve has good fluid control characteristics.When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated by the valve is very small, so it has good flow control characteristics.Butterfly valve has bullet seal and metal seal two types of seal.Resilient seal valve, seal ring can be embedded in the body or attached to the edge of the disc.

Metal sealed valves generally have longer life than elastomally sealed valves, but complete sealing is difficult to achieve.Metal seal can adapt to higher working temperature, while elastic seal has the defect of temperature limitation.

If butterfly valves are required for flow control, it is important to choose the correct size and type of valve.The structure principle of butterfly valve is especially suitable for making large diameter valve.Butterfly valve is not only widely used in oil, gas, chemical industry, water treatment and other general industries, but also used in the cooling water system of thermal power stations.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor