Adoptive Standards

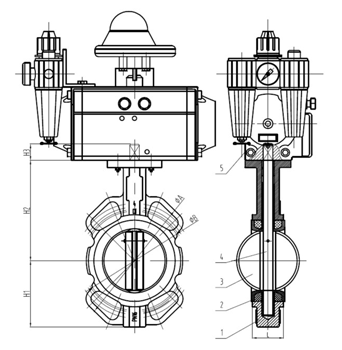

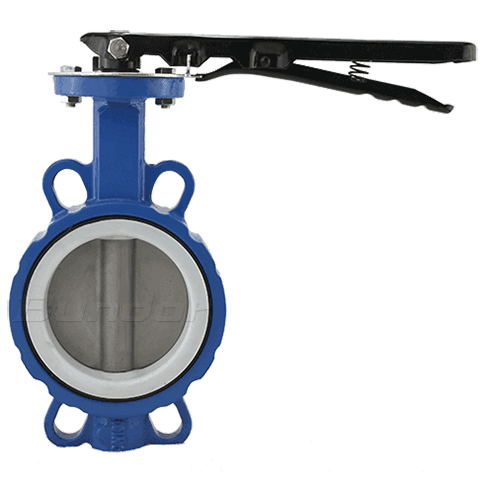

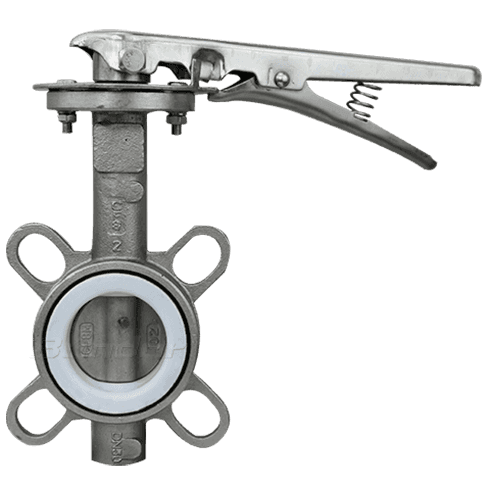

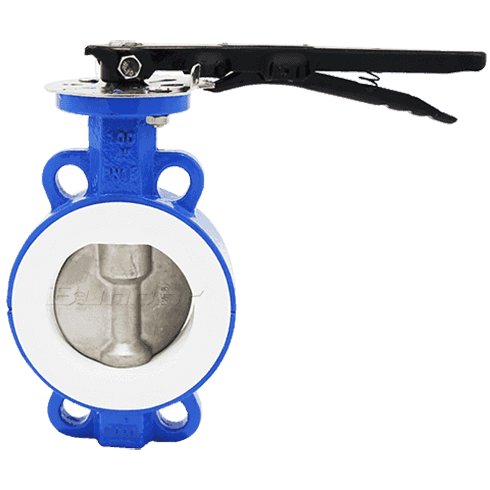

Valve Design: API 609, MSS SP-67

Face To Face: API 609, MSS SP-67, DIN3202, BS EN558-1

Pressure Test: API 598

Flange Drilling: ANSI B16.1 class125, BS4504 PN10/PN16, DIN2501 PN10/PN16

Top Flange: ISO5211

Product Advantage

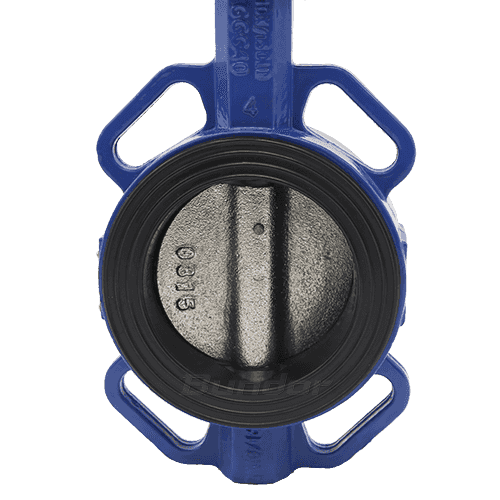

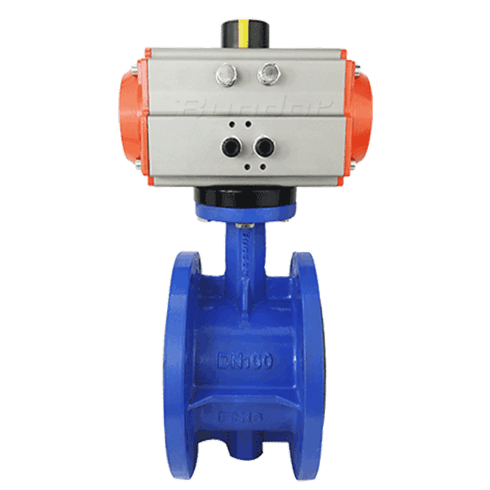

1.Bundor Valve patent product,Patent Number: 201510315321.5;201520267217.9,The product side flange complies with many national and international standards such as GB, DIN, GOST, ANSI, BS, JIS,etc.

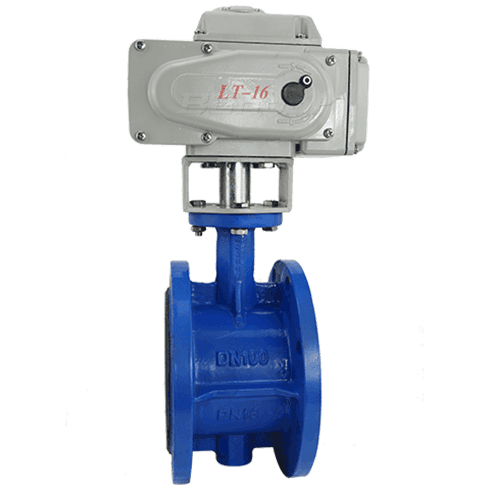

2.Valve body procurement QT450-10 material, spheroidization rate of 3 or more, mechanical properties fully up to standard, tensile strength 450Mpa, elongation rate greater than 10%, not easy to crack, crack

3.The valve body is solid body, the same DN weight is heavier than other manufacturers

4.Seat rubber uses standard EPDM rubber, making the butterfly valve's resilience and tension super stable and reliable, opening and closing more than 10,000 times without leakage.

5.The valve body uses an electrostatic powder thermal spraying process with a spray thickness of 250μm. The valve body is heated at 200°C for 3 hours, and the powder is cured at 180°C for 2 hours. After natural cooling, the surface adhesion is increased by 2 times than that of the ordinary powder, making it more environmentally friendly and weatherproof. Higher, to ensure that the valve body is not discolored for 36 months;

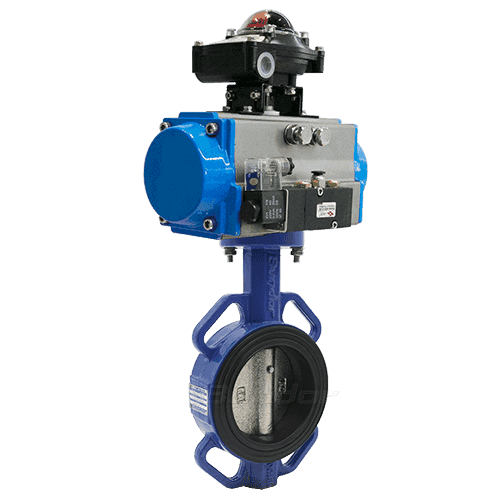

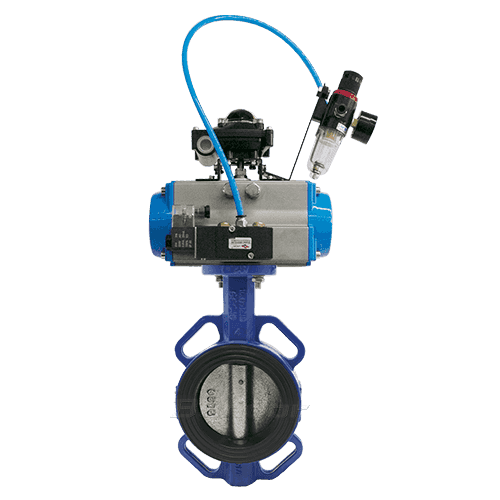

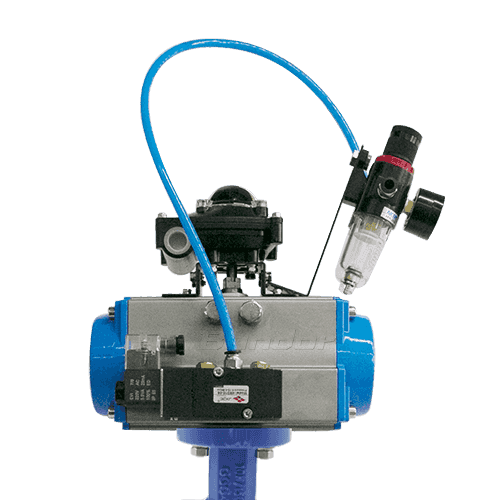

6.Pneumatic head adopts double-piston rack structure, precise meshing, high efficiency and constant output torque.

7.The cylinder body is an extruded aluminum alloy and hard anodized. The inner surface has a hard texture and high strength and hardness. The use of low-friction materials made of sliding bearings, to avoid direct contact between the metal, low friction coefficient, flexible rotation, long service life

8.Introducing the PE heat-shrinking plastic packaging technology of electronic products. Each of the products of Ruderland is individually wrapped with a heat-shrinkable film and has a built-in desiccant. The air dust is isolated to facilitate storage and avoid corrosion caused by moisture.

9.Every Ruide product has its own two-dimensional code identification from the accessories to the finished product, the unique ID ID number, to ensure that the product can be traced

10.The Gende intelligent detection equipment integrates standard data measurement and pressure detection. Each inspection report is automatically generated. Each data and report is saved for 5 years, ensuring that the factory qualification rate reaches 100%.

11.Bundor brand products are underwritten by Pacific Insurance Company with 10 million quality. The warranty is 2 years. Within two years, one is lost and one is lost. The quality of the product is unconditional.

Standard Test

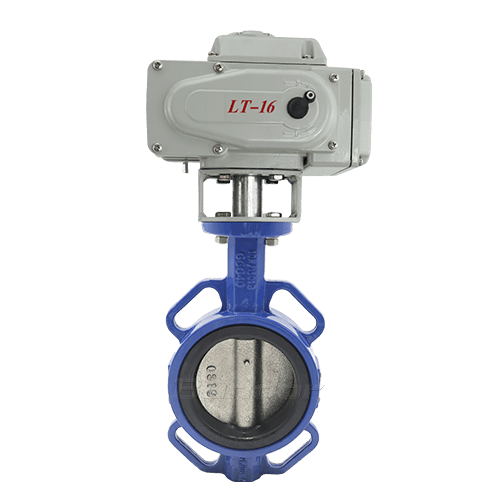

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor