The difference between manual valve, pneumatic valve and electric valve

Posted by Bundor valve

This article introduces you to the difference between manual valves, pneumatic valves, and electric valves.

Manual valve

The manual valve is operated by the operator to open and close the valve by manpower with the help of the handle or handwheel. When the opening and closing torque of the valve is large, a turbine device needs to be installed between the handle or the handwheel and the valve stem, which is more labor-saving to operate. . Usually, the opening and closing direction of the manual valve is to pull the handle or handwheel of the valve, turn it clockwise to close, and turn it counterclockwise to open the valve.

Pneumatic valves and electric valves are also equipped with manual devices, in case the actuator fails, the valve can be opened and closed by manual operation.

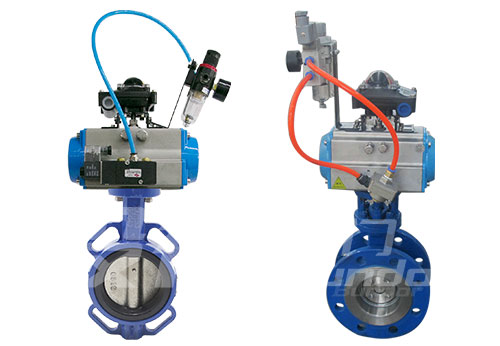

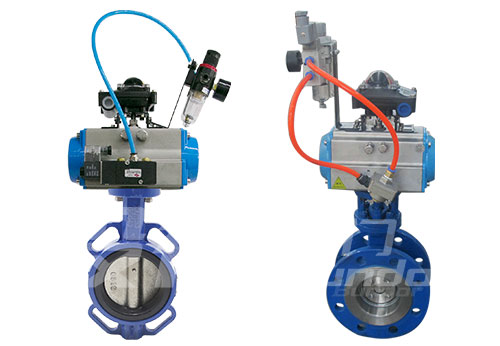

Pneumatic valves

Pneumatic valve is a valve that is driven by a pneumatic actuator and powered by compressed air. This type of valve has a simple structure and is easy to maintain, but it is large in size and requires an air source and an air purification device; the actuator and adjustment mechanism of the pneumatic actuator are unified whole.

Pneumatic valves use gas as the power medium, which has the advantages of high safety and low requirements for the use environment. However, due to the compressibility of gas, pneumatic actuators with relatively low stiffness have slow response, poor resolution, low control accuracy, and weak anti-deviation ability. Undesirable vibration of the device. And its energy-to-weight ratio is poor, power density is low, and the pneumatic actuator with large driving force is extremely complex, heavy and expensive.

Electric valve

The electric valve is a valve that drives the switch by an electric actuator. The electric actuator can output a relatively constant driving force, has strong anti-deviation ability, and has higher control accuracy than the pneumatic actuator. It can automatically maintain its position without the help of other auxiliary systems.

Electric actuators have the characteristics of simple operation and easy remote control. However, their structure is complex, and they are prone to failure due to load. There are often low positioning accuracy, over-opening and closing, motor burnout, gear box wear, etc., and the maintenance cost is high. Too frequent adjustment will cause the motor to heat up, and the reduction gear will be easily worn. In addition, the electric actuator runs slowly, it is difficult to achieve a large driving force, and there are problems such as difficulty in realizing over-protection and poor position.

Manual valve

The manual valve is operated by the operator to open and close the valve by manpower with the help of the handle or handwheel. When the opening and closing torque of the valve is large, a turbine device needs to be installed between the handle or the handwheel and the valve stem, which is more labor-saving to operate. . Usually, the opening and closing direction of the manual valve is to pull the handle or handwheel of the valve, turn it clockwise to close, and turn it counterclockwise to open the valve.

Pneumatic valves and electric valves are also equipped with manual devices, in case the actuator fails, the valve can be opened and closed by manual operation.

Pneumatic valves

Pneumatic valve is a valve that is driven by a pneumatic actuator and powered by compressed air. This type of valve has a simple structure and is easy to maintain, but it is large in size and requires an air source and an air purification device; the actuator and adjustment mechanism of the pneumatic actuator are unified whole.

Pneumatic valves use gas as the power medium, which has the advantages of high safety and low requirements for the use environment. However, due to the compressibility of gas, pneumatic actuators with relatively low stiffness have slow response, poor resolution, low control accuracy, and weak anti-deviation ability. Undesirable vibration of the device. And its energy-to-weight ratio is poor, power density is low, and the pneumatic actuator with large driving force is extremely complex, heavy and expensive.

Electric valve

The electric valve is a valve that drives the switch by an electric actuator. The electric actuator can output a relatively constant driving force, has strong anti-deviation ability, and has higher control accuracy than the pneumatic actuator. It can automatically maintain its position without the help of other auxiliary systems.

Electric actuators have the characteristics of simple operation and easy remote control. However, their structure is complex, and they are prone to failure due to load. There are often low positioning accuracy, over-opening and closing, motor burnout, gear box wear, etc., and the maintenance cost is high. Too frequent adjustment will cause the motor to heat up, and the reduction gear will be easily worn. In addition, the electric actuator runs slowly, it is difficult to achieve a large driving force, and there are problems such as difficulty in realizing over-protection and poor position.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor