What are the types of gate valves

Posted by Bundor valve

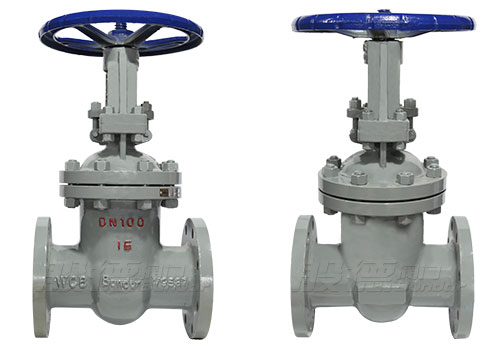

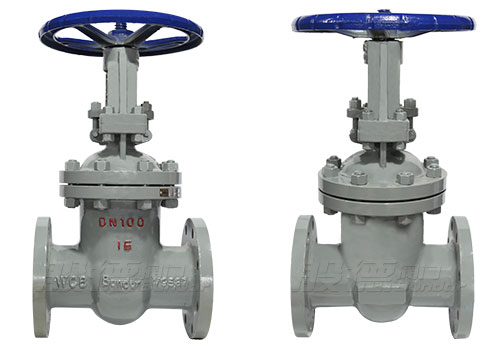

Gate valves are divided into open stem gate valves and dark stem gate valves according to the structure and movement of the stem. The stem of the rising stem gate valve drives the gate to rise and fall together, and the drive thread on the valve stem is outside the valve body. Therefore, the opening and closing and position of the gate can be intuitively judged according to the movement direction and position of the valve stem, and the drive thread is easy to lubricate and is not corroded by fluids, but it requires a larger installation space. The transmission thread of the dark stem gate valve is located inside the valve body. During the opening and closing process, the valve stem only rotates, and the gate rises and falls in the valve body. Therefore, the height dimension of the valve is small. Concealed stem valve gate is usually equipped with an opening and closing position indicator above the valve cover, which is suitable for the environment with small space and large dust content such as ships and pipe trenches.

Gate valves can also be divided into wedge type and parallel type according to the structure of the gate.

Wedge gate can be divided into rigid single gate, elastic single gate and double gate.

The wedge-type rigid single gate is simple in structure, small in size and reliable in use. However, the processing and matching accuracy of the wedge angle is relatively high, and it is prone to clamping and scratching. It is suitable for gate valves with various media and pressures at room temperature and medium temperature. The wedge-type elastic single gate can achieve a good seal by the compensation of the slight elastic deformation of the gate. The temperature change is not easy to cause wedge dead, and the wedge angle accuracy is low. However, it should be prevented that the closing torque is too large and the gate loses its elasticity. It is suitable for gate valves of various temperatures and pressures. The wedge-type double gate has low requirements on the machining accuracy of the wedge angle of the sealing surface, and is easy to seal. However, the structure is more complex, there are many parts, and the shape and weight of the valve are large.

The parallel single gate has a simple structure and cannot be forced to seal by itself. In order to ensure its tightness, a fixed or floating soft seal is generally used. It is suitable for medium and low pressure, large and medium calibers, and the medium is oil or gas and natural gas. . .

The parallel double gate generally generates sealing force through the top wedge, the relative movement between the sealing surfaces is small, and it is not easy to be scratched. It is mostly used for low pressure, medium and small diameter gate valves.

Gate valves can also be divided into wedge type and parallel type according to the structure of the gate.

Wedge gate can be divided into rigid single gate, elastic single gate and double gate.

The wedge-type rigid single gate is simple in structure, small in size and reliable in use. However, the processing and matching accuracy of the wedge angle is relatively high, and it is prone to clamping and scratching. It is suitable for gate valves with various media and pressures at room temperature and medium temperature. The wedge-type elastic single gate can achieve a good seal by the compensation of the slight elastic deformation of the gate. The temperature change is not easy to cause wedge dead, and the wedge angle accuracy is low. However, it should be prevented that the closing torque is too large and the gate loses its elasticity. It is suitable for gate valves of various temperatures and pressures. The wedge-type double gate has low requirements on the machining accuracy of the wedge angle of the sealing surface, and is easy to seal. However, the structure is more complex, there are many parts, and the shape and weight of the valve are large.

The parallel single gate has a simple structure and cannot be forced to seal by itself. In order to ensure its tightness, a fixed or floating soft seal is generally used. It is suitable for medium and low pressure, large and medium calibers, and the medium is oil or gas and natural gas. . .

The parallel double gate generally generates sealing force through the top wedge, the relative movement between the sealing surfaces is small, and it is not easy to be scratched. It is mostly used for low pressure, medium and small diameter gate valves.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor