Installation instructions and steps of sandwich butterfly valve

Posted by Bundor valve

Sandwich butterfly valve is one of the most common types of valves in industrial pipelines. The structure of the sandwich butterfly valve itself is relatively small. Just put the butterfly valve into the middle of the flange at both ends of the pipeline, and lock the butterfly valve through the pipe flange and sandwich butterfly valve with a double-headed bolt to control the fluid medium of the pipeline.Sandwich butterfly valve is especially suitable for space narrow or short distance between the pipe, the butterfly valve in the fully open position, the thickness of the butterfly plate is the only resistance when the media flow through the valve body, so the pressure drop generated by the valve is very small, it has a better flow control characteristics.

Description before installation of sandwich butterfly valve:

1.Before the installation starts, clean the external objects on the piping with air spray, and clean the inner surface with clean water.

2.Carefully check whether the valve usage is consistent with its performance specification;(temperature, pressure)

3.Check whether there are sundries in the valve passage and sealing surface, and remove them timely.

4. The valve should be installed in time after opening the box. Do not loosen any fastening screws or nuts on the valve at will.

5.Sandwich butterfly valve must use special butterfly valve flange.

6.Electric butterfly valve can be installed in any Angle of the pipeline, in order to maintain the convenience of inverted installation is recommended.

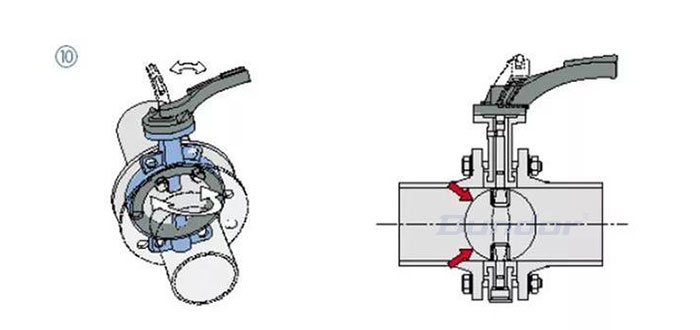

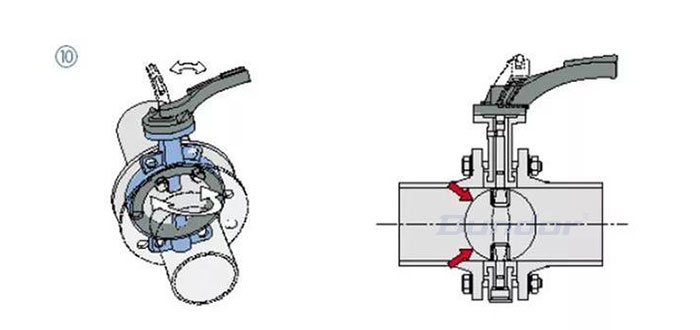

7.Butterfly valve flange in the installation must ensure that the flange face and the seal rubber, screw evenly tightened, sealing surface must be fully fitted;If the screw tightening force is not uniform, the rubber bump will appear to jam the disc, or against the disc stem leakage.

Installation steps of clip butterfly valve:

The correct installation of the clamping butterfly valve is related to the sealing degree of the butterfly valve and whether the valve will leak, including the safety in the operating conditions, the user shall understand the installation process.

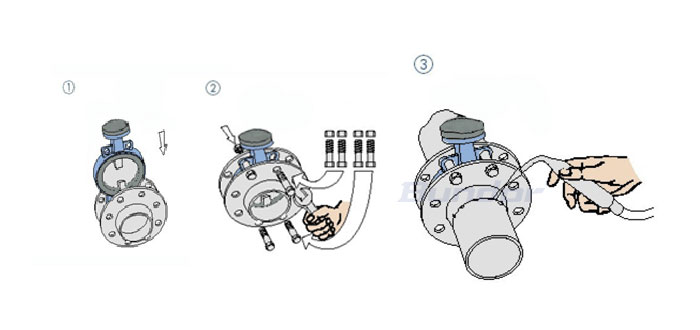

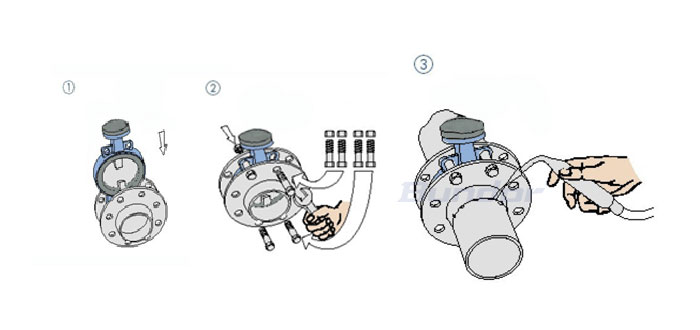

1.Place the valve between the two pre-installed flanges as shown, and note that the bolt holes should be aligned neatly.

2.Insert four pairs of bolts and nuts into the flange hole gently and tighten the nuts slightly to correct the flatness of the flange face.

3.Fix the flange on the pipeline by spot welding.

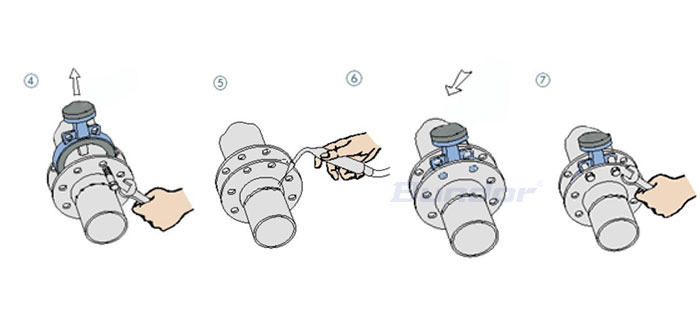

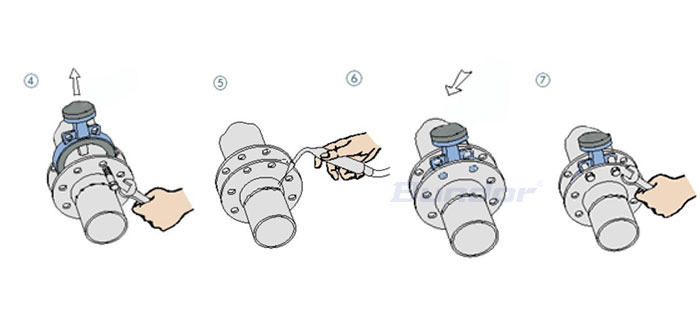

4.Remove the valve.

5.Fix the flange on the pipeline with complete welding.

6.Install the valve after the welding joint is cooled.Ensure that the valve has enough free space in the flange to prevent damage to the valve, and ensure that the valve plate has a certain degree of opening.

7.Correct valve position and tighten the four pairs of bolts (be careful not to tighten them too tightly).

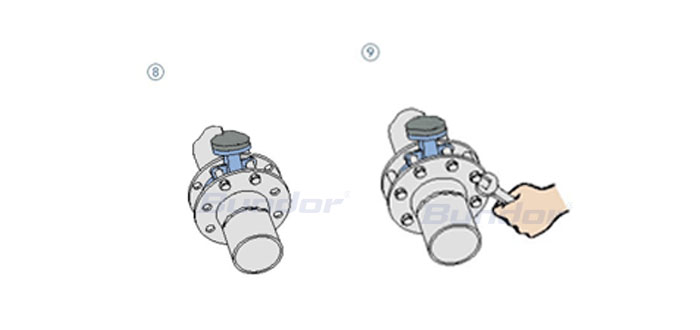

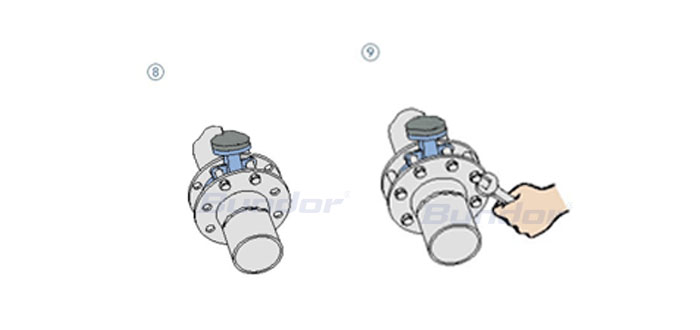

8.Open the valve, ensure that the valve plate can open and close freely, and then slightly open the valve plate.

9.Tighten all nuts with cross balance.

10.Confirm again that the valve can be opened and closed freely. Note: confirm that the valve plate does not touch the pipe.

Clamping butterfly valve installation in the first place before the installation must be flat, remember not to knock at will, in the installation of the time it will be pulled into the length of installation, in the field of pipeline design, without special permission is not free to remove the clamping butterfly valve, this is we want to know before the installation.At the same time we also know that the clamping butterfly valve can be installed in any position, but the clamping butterfly valve installation after the completion of the need to lay along the butterfly valve, the clamping butterfly valve to do a bracket, and once the bracket is made, in the use of the bracket is strictly prohibited to be removed.

Description before installation of sandwich butterfly valve:

1.Before the installation starts, clean the external objects on the piping with air spray, and clean the inner surface with clean water.

2.Carefully check whether the valve usage is consistent with its performance specification;(temperature, pressure)

3.Check whether there are sundries in the valve passage and sealing surface, and remove them timely.

4. The valve should be installed in time after opening the box. Do not loosen any fastening screws or nuts on the valve at will.

5.Sandwich butterfly valve must use special butterfly valve flange.

6.Electric butterfly valve can be installed in any Angle of the pipeline, in order to maintain the convenience of inverted installation is recommended.

7.Butterfly valve flange in the installation must ensure that the flange face and the seal rubber, screw evenly tightened, sealing surface must be fully fitted;If the screw tightening force is not uniform, the rubber bump will appear to jam the disc, or against the disc stem leakage.

Installation steps of clip butterfly valve:

The correct installation of the clamping butterfly valve is related to the sealing degree of the butterfly valve and whether the valve will leak, including the safety in the operating conditions, the user shall understand the installation process.

1.Place the valve between the two pre-installed flanges as shown, and note that the bolt holes should be aligned neatly.

2.Insert four pairs of bolts and nuts into the flange hole gently and tighten the nuts slightly to correct the flatness of the flange face.

3.Fix the flange on the pipeline by spot welding.

4.Remove the valve.

5.Fix the flange on the pipeline with complete welding.

6.Install the valve after the welding joint is cooled.Ensure that the valve has enough free space in the flange to prevent damage to the valve, and ensure that the valve plate has a certain degree of opening.

7.Correct valve position and tighten the four pairs of bolts (be careful not to tighten them too tightly).

8.Open the valve, ensure that the valve plate can open and close freely, and then slightly open the valve plate.

9.Tighten all nuts with cross balance.

10.Confirm again that the valve can be opened and closed freely. Note: confirm that the valve plate does not touch the pipe.

Clamping butterfly valve installation in the first place before the installation must be flat, remember not to knock at will, in the installation of the time it will be pulled into the length of installation, in the field of pipeline design, without special permission is not free to remove the clamping butterfly valve, this is we want to know before the installation.At the same time we also know that the clamping butterfly valve can be installed in any position, but the clamping butterfly valve installation after the completion of the need to lay along the butterfly valve, the clamping butterfly valve to do a bracket, and once the bracket is made, in the use of the bracket is strictly prohibited to be removed.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor