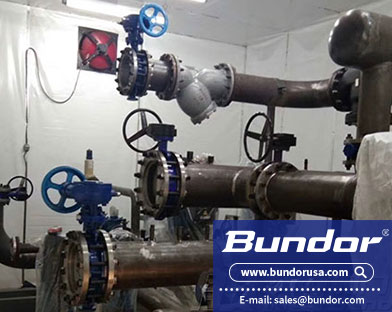

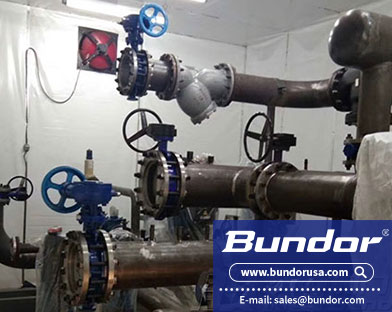

Installation position of butterfly valve

Posted by Bundor valve

Butterfly valve installation position is very particular, in the installation should take into account the operator, convenient operator of the butterfly valve operation.The specific installation position, the handle or hand wheel of the manual butterfly valve is about 1.2 meters away from the operation ground, which is almost to the chest position of adults. This installation position is the most suitable for manual operation, and the switch will save effort.

Do not install too high, let the operator head operation, if the pipeline is acid and alkali, toxic media, will threaten the personal safety of the operator, butterfly valve can not be installed upside down.

In addition, there are some matters needing attention when butterfly valve is installed:

1. The inner mouth of the flange on the pipe must be aligned, and the rubber sealing ring of the butterfly valve must be pressed, without the use of sealing gasket.If the flange inner mouth deviates from the butterfly valve rubber sealing ring, there will be leakage from the stem or other external leakage.

2. Before fixing the valve, close the valve plate several times to ensure that there is no blocking phenomenon before tightening the fixing nut completely.If there is a jam will lead to the butterfly valve can not be fully opened or closed, electric or pneumatic valve will appear the actuator will stem twisted deformation phenomenon.

3. It is strictly prohibited to weld the flange after installing the butterfly valve, otherwise it will burn out the rubber sealing ring of the butterfly valve.

4. When replacing the lower part of the electric or pneumatic butterfly valve, it must be closed to close and open to open before assembly, and the whole machine can be adjusted and installed on the pipeline.

Do not install too high, let the operator head operation, if the pipeline is acid and alkali, toxic media, will threaten the personal safety of the operator, butterfly valve can not be installed upside down.

In addition, there are some matters needing attention when butterfly valve is installed:

1. The inner mouth of the flange on the pipe must be aligned, and the rubber sealing ring of the butterfly valve must be pressed, without the use of sealing gasket.If the flange inner mouth deviates from the butterfly valve rubber sealing ring, there will be leakage from the stem or other external leakage.

2. Before fixing the valve, close the valve plate several times to ensure that there is no blocking phenomenon before tightening the fixing nut completely.If there is a jam will lead to the butterfly valve can not be fully opened or closed, electric or pneumatic valve will appear the actuator will stem twisted deformation phenomenon.

3. It is strictly prohibited to weld the flange after installing the butterfly valve, otherwise it will burn out the rubber sealing ring of the butterfly valve.

4. When replacing the lower part of the electric or pneumatic butterfly valve, it must be closed to close and open to open before assembly, and the whole machine can be adjusted and installed on the pipeline.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor