Characteristics and structure of ball valve

Posted by Bundor valve

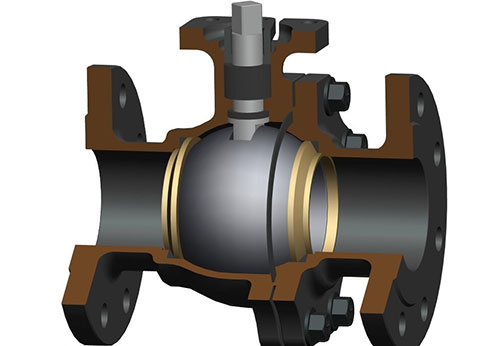

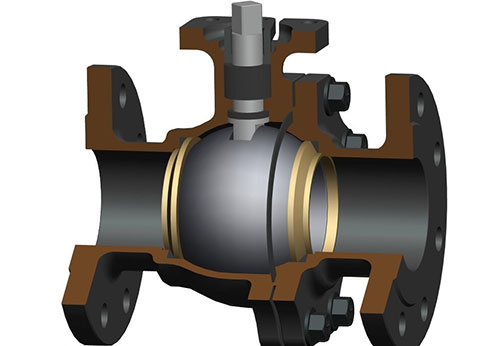

The ball valve is evolved from the plug valve, which can be opened and closed with only a 90° rotation and a small torque. The valve body cavity of the ball valve is straight through, and the medium flow resistance is close to 0. The structure of the ball valve is also relatively simple, consisting of a valve body, a sphere, a valve seat, a valve stem, a bracket and a drive device.

The ball valve can be divided into three types according to the structure: floating ball valve, fixed ball valve and elastic ball valve.

c

c

1.Has the lowest flow resistance.

2.It will not get stuck when working, and can be used in corrosive media and low-boiling liquids.

3.In a large pressure and temperature range, it can achieve complete sealing.

4.It can realize rapid opening and closing, and when the valve is opened and closed quickly, the operation has no impact.

5.When fully open and fully closed, the sealing surface of the ball and the valve seat is isolated from the medium, which will not cause erosion of the sealing surface.

The ball valve can be divided into three types according to the structure: floating ball valve, fixed ball valve and elastic ball valve.

c

c

- Floating ball valve: The ball is floating. Under the action of medium pressure, the ball can produce a certain displacement and press tightly on the sealing surface of the outlet end to ensure the sealing of the outlet end. This kind of structure ball valve is widely used in medium and low pressure pipelines.

- Fixed ball valve: The ball is fixed and does not move after being pressed. Bearings are usually installed on the upper and lower shafts of the ball, and the operating torque is small, which is suitable for high-pressure and large-diameter valves.

- Elastic ball valve: The ball is elastic. Both the ball and the valve seat sealing ring are made of metal materials, and the sealing specific pressure is very large. The pressure of the medium itself cannot meet the sealing requirements, and external force must be applied. This valve is suitable for high temperature and high pressure medium.

1.Has the lowest flow resistance.

2.It will not get stuck when working, and can be used in corrosive media and low-boiling liquids.

3.In a large pressure and temperature range, it can achieve complete sealing.

4.It can realize rapid opening and closing, and when the valve is opened and closed quickly, the operation has no impact.

5.When fully open and fully closed, the sealing surface of the ball and the valve seat is isolated from the medium, which will not cause erosion of the sealing surface.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor