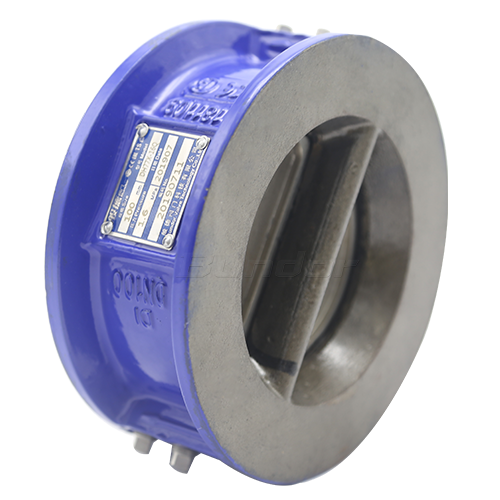

Features:

Applicable medium:Water and non-corrosive liquids

Suitable temperature:- 20 ~ 120 ℃

Application field:Municipal construction, water conservancy projects, water supply and drainage, water treatment, etc

Product advantages:

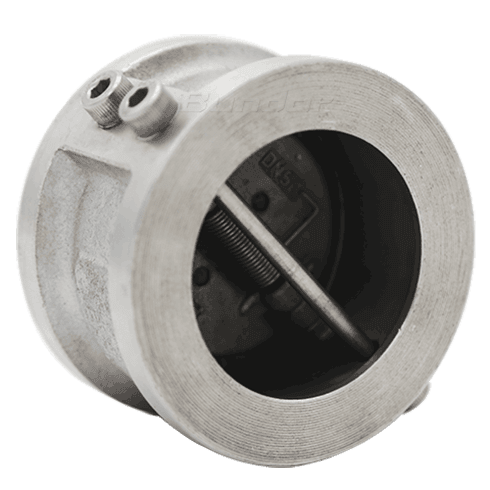

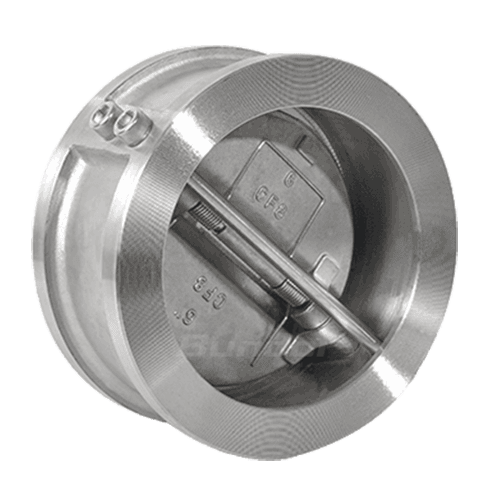

1. The spring adopts ni-base alloy x-750, which has good corrosion resistance, seawater resistance and stable torque, and can provide material proof.

2. The spring is treated with solid solution, with high tensile strength of 910MPa, brinell hardness HB350, high hardness and good fatigue resistance. After heat treatment, the residual deformation stress is eliminated, which greatly improves the service life of the spring.

3. Rubber is treated with special process to avoid rubber aging after high-temperature spraying and give full play to rubber performance

4. The valve body adopts the casting process of production line, with smooth appearance, clear casting, high dimensional accuracy and guaranteed delivery time.

5. The mechanical properties of the main material fully meet the qt450-10 standard, and the spheroidization rate can reach level 3.

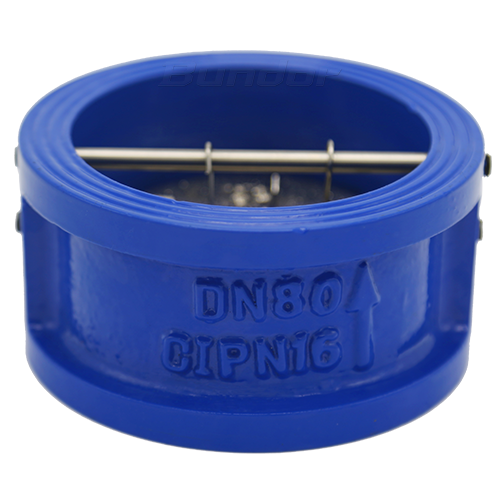

6. The valve design fully conforms to the JB/T8937 standard, with large body shape, heavy weight, standard wall thickness and ensuring pressure

7. The valve stem is made of 304 material to prevent rust and corrosion

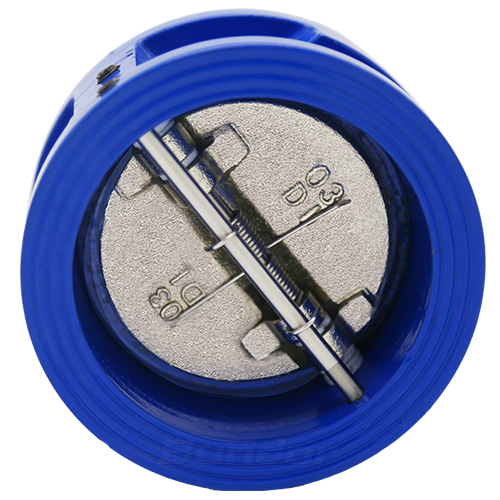

8. The sealing cover of butterfly plate and valve body shall be ground to ensure its smoothness and smoothness, ensure sealing of disc and valve body, and the sealing cover of valve shall not leak when no pressure is applied. All products can achieve static pressure 0 leakage

9. The inner cavity rubber of valve body adopts advanced vulcanization process to ensure that the binding strength of rubber and valve body is greater than 1.732mpa, effectively avoiding the shedding of seats in the service process.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor