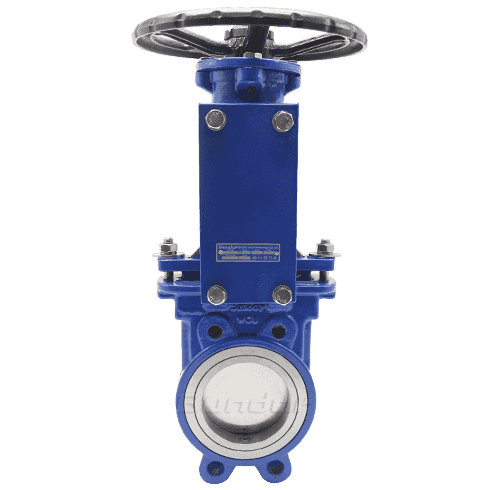

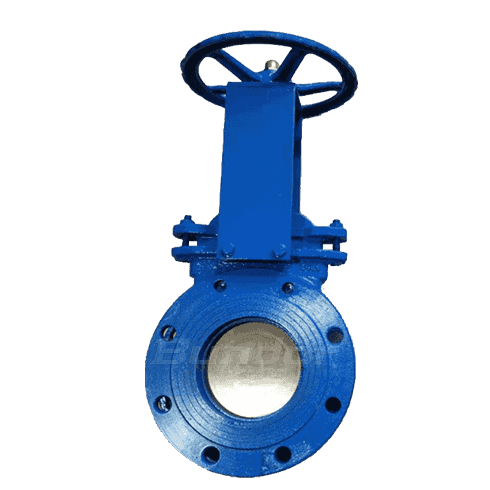

The Bundor Series 745 features a one piece urethane liner molded throughout the body and chest for reliable service in abrasive and corrosive applications.

The one piece, durable ductile iron body is offered in a compact wafer style for ease of handling and installation.

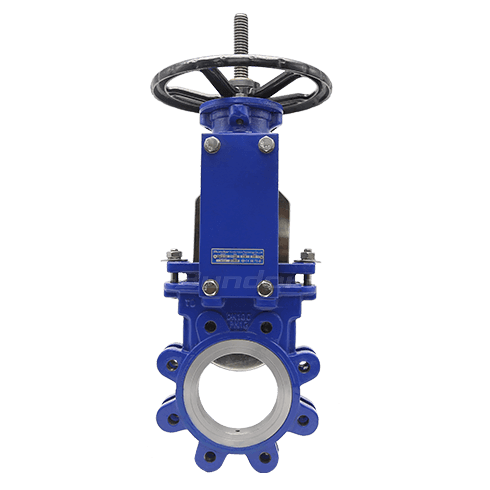

1. Designed for easy, quick conversion between manual and pneumatic actuation. Featuring a lubricant injection port for continuous, smooth operation with minimal maintenance.*

2. Clevis design and horizontal bolting stabilizes gate ensuring proper alignment.

3. Standard multi-layer square packing provides exceptional gland sealing.

4. Optional energized quad seal packing for enhanced gland sealing.

5. Urethane body liner is rated up to 80째C/176째F and completely protects valve body from abrasive line media. (UMP 241 90 Shore, PTMEG-TDI)

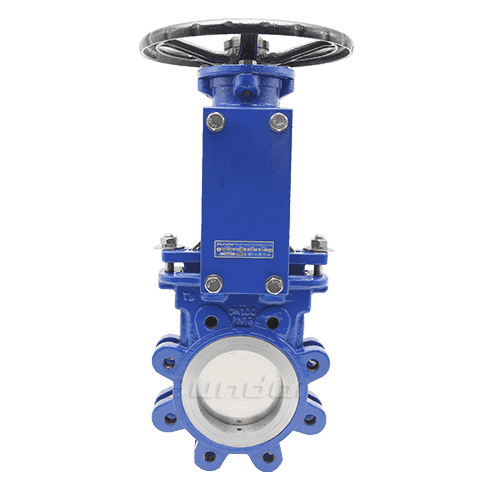

6. Deflection resistant gate design ensures consistent alignment for industry leading durability.

7. Lugged body suitable for all mounting orientations including dead-end service.

Product Advantage

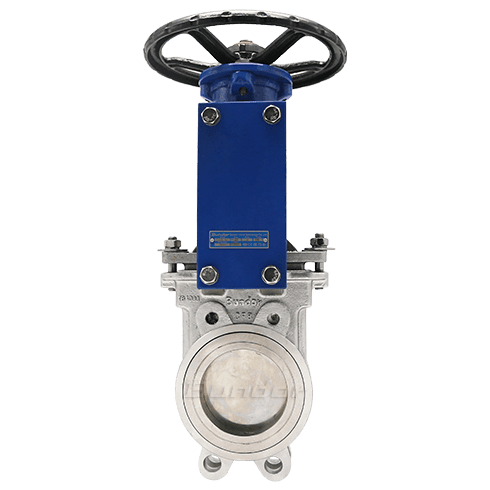

1,The valve body is made of precision casting, the precise geometry makes the north of the valve body not need any finishing, so as to ensure the tightness of the valve.

2,The body is made of ductile iron QT450-10, shall not be broken by transportation, collision or installation.

3,The valve body adopts streamlined design, so that the medium moves straight in the valve cavity, the flow resistance is smaller and the flow area is larger.

4,The valve adopts bidirectional sealing design, and the installation direction and medium flow direction are not limited.

5,The inside and outside of the valve bodyadopt powder epoxy resin electrostatic coating, which can effectively prevent corrosion and rust caused by contact between valve body and medium, and can be used in sewage system.

6,The valve plate adopts high-quality overall rubber coating, the use of advanced technology makes the vulcanized rubber vulcanization after the valve plate to ensure accurate geometry, and the rubber and ductile iron gate connection is firm and not easy to fall off with good elastic memory, so as to ensure the stable performance of the valve sealing.

7,The bottom of the valve body adopts no groove design, and does not cause accumulation of impurities or dirt, thereby effectively avoiding the leakage caused by impurities scratching of the valve seat.

8,The valve stem is designed with three "O" ring seal. The friction resistance of the switch can be reduced, water leakage is greatly reduced, and the sealing ring can be replaced without cutting off water.

9,The screw made of aluminum bronze material, so the switch is more smooth, not easy to rust, difficult blockage.

10,The overall of valve adopt non rising stem design, reducing the valve, especially large diameter valve installation space.

11,For the installation of valves using in deep well and underground pipe, deep well connecting cap or lengthening rod mechanism can be provided according to customer requirements.

12,Bundor company specialized intentions since 1994, has a professional production, sales, research, after-sales team, is your strong backing of sales and use.

Standard Test

Shell test

The cold test of the valve body, which is connected with the valve body and the valve cover,

is carried out to test the structural strength, pressure resistance and compactness of the

valve housing, including the whole housing in the fixed connection

Closure test

Test of sealing performance between valve opening and closing parts and seat seal, between

valve body and valve seat

Test pressure

The display pressure of the valve lumen during the experiment

Test fluid

Liquid or gas for pressure test of valves

Test fluid temperature

The temperature of the liquid or gas used for the pressure test of the valve shall be in the

range of 5-40 unless otherwise specified

Resilient seats

Seals made of non-metallic elastic materials, solid and semisolid lubricants, etc.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor