Features:

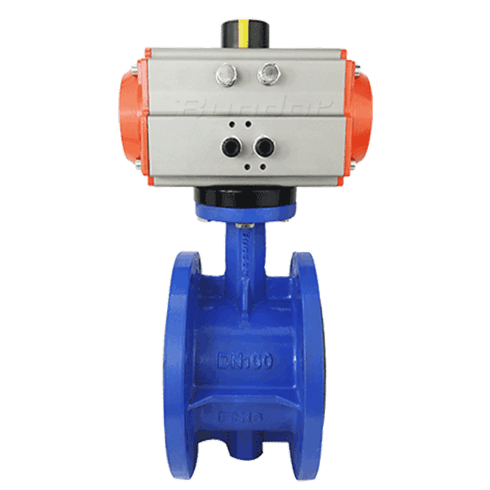

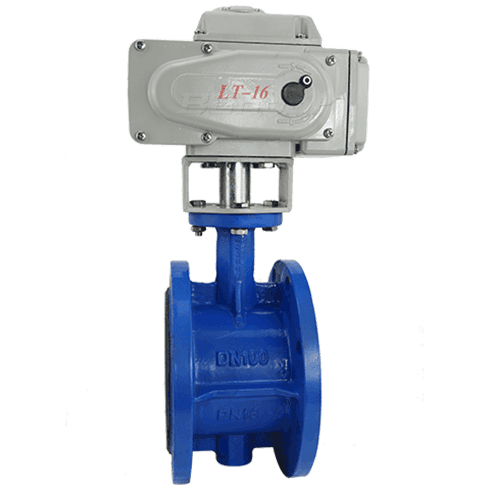

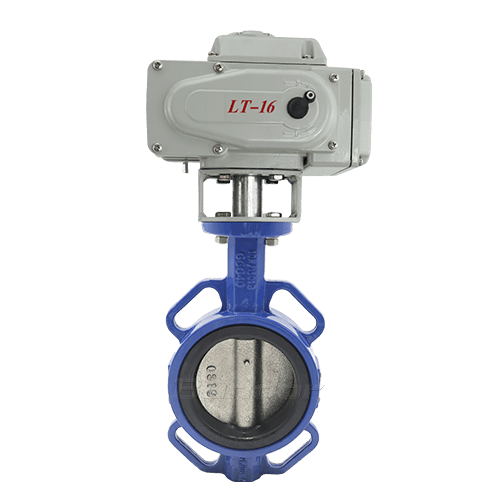

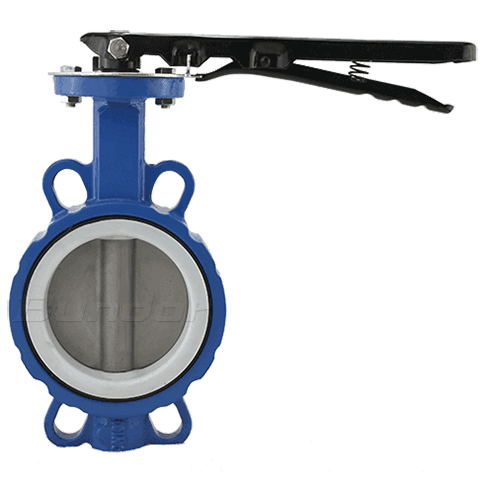

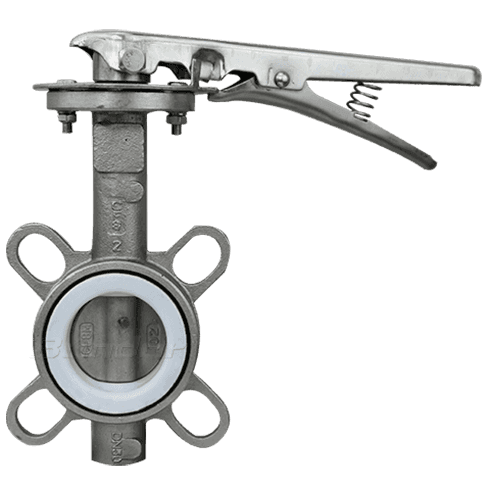

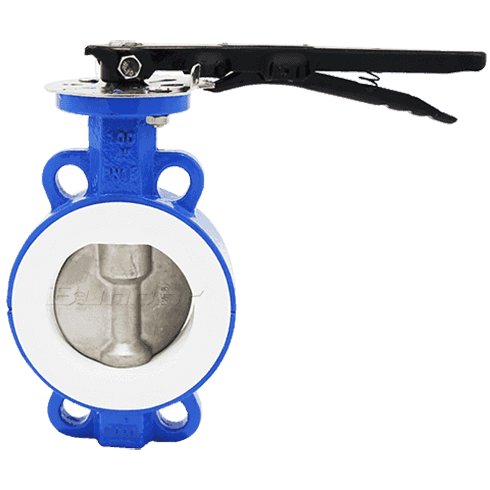

Applicable medium:Clear water and neutral liquid

Suitable temperature:- 20 ~ 120 ℃

Application field:Municipal construction, water conservancy projects, water supply and drainage, water treatment, etc

Product advantages:

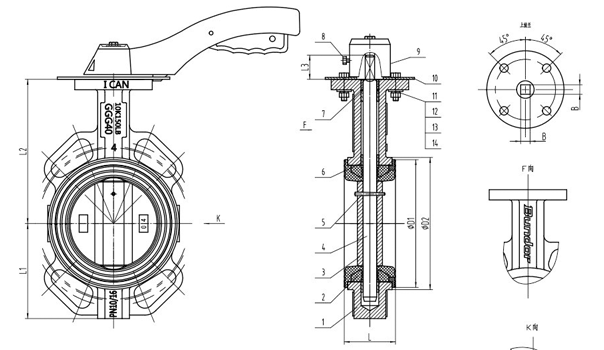

1. The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2. The thickness of valve body meets the requirement of GB 26640, and the thickness and pressure strength are guaranteed.

3. The valve body is made of qt450-10 material and has 3 grades of spheroidization rate, with stronger mechanical properties, tensile strength of 450Mpa and extension rate of more than 10%. Compared with cast iron body, the tensile strength of the same thickness is twice that of cast iron body, and the applicable working pressure is higher.

4. The seat is made of imported rubber material with 50% adhesive content.The valve sealing is reliable, the opening and closing moment is stable, the valve seat has a long service life, and the opening and closing times can reach more than 10000.

5. The seat is a wide-edge seat, which is favorable for valve installation, wide contact surface with flange boss on pipeline, reliable sealing performance, and the installation precision is lower than the narrow-edge seat. Seat axial with concave table, with o-ring, can realize seat axial secondary seal.

6. The valve shaft and valve body are equipped with 4 oil-free bearings and 3 o-type seals. The valve shaft supports more vigorously and the axial seal is more reliable.

7. Ultrasonic cleaning shall be carried out before packing of each valve, so as to prevent contamination and particulate impurities from remaining in the valve body, ensure cleanliness of the valve and prevent contamination of the water body of the pipeline by the valve itself.

8. The body is sprayed with epoxy resin plastic powder from Aksu, a world-famous brand, which can be deposited thicker and have stronger adhesion after melt curing.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor